About recycling

The earth offers us all the raw materials we need. These raw materials are not infinite so we need to use them sparingly. Nature shows us how perfect cycles work. Valuable materials don’t dissolve into thin air – the existing resources are used for new things.

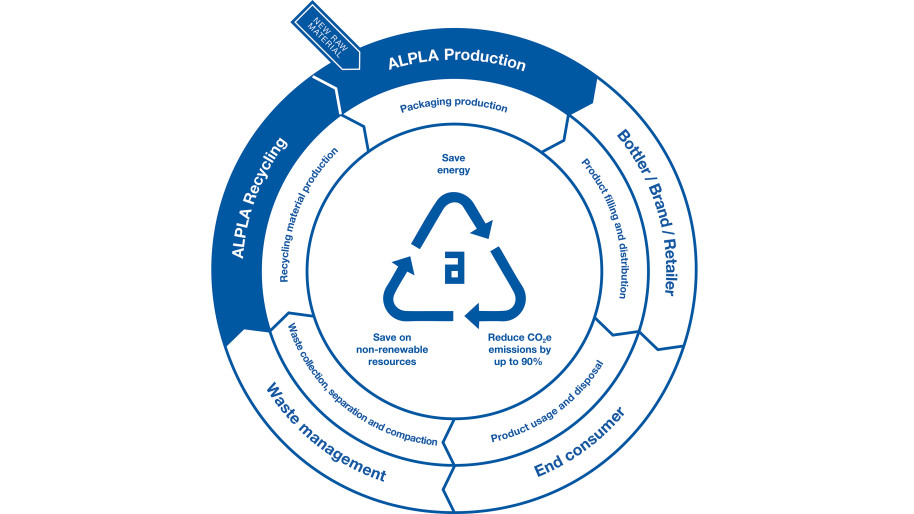

We close the loop so that packaging can be turned into packaging again.

Used plastics are valuable materials

Used packaging is anything but useless waste. Quite the opposite, in fact – we see it as a valuable raw material which we can turn into high-quality recyclates using cutting-edge technologies. These recyclates are then used to produce new packaging in line with a functioning circular economy.

This is our ‘closed-loop approach’.

Concentrated expertise

The recycling and production plants under the aegis of the ALPLA Group mutually benefit from their many years of expertise. The plastics-processing businesses know exactly what’s needed to turn recycled materials into new packaging solutions. Product development and process technology experts work hand in hand with recycling experts and together they continuously further develop the materials and manufacturing processes.

Why recycling makes sense

Recycling gives used plastics value. This promotes the elaboration of efficient recyclables collection, allows regional materials cycles to be closed and boosts the further development of sustainable recycling technologies.

After all, plastics can be recycled very effectively and energy-efficiently. Recyclates cause up to 90 per cent fewer greenhouse gas emissions than virgin material. What’s more, the more valuable materials are recycled, the less waste ends up as landfill or in the environment.

Recycling is therefore a fundamental part of a functioning circular economy.

Milestones

ALPLA first moved into recycling back in 1990 with its first post-consumer recycled (PCR) bottle. The subsequent milestones include:

2005

ALPLA becomes a joint venture partner in PET recycling at IMER, Mexico.

2005

PET Recycling Team GmbH is founded in Wöllersdorf, Austria.

2010-2012

ALPLA acquires PET Recycling Team in Wöllersdorf, Austria.

2010-2012

ALPLA PET Recycling Team plant built in Radomsko, Poland.

2018

As an Ellen MacArthur Foundation partner, ALPLA sets itself the targets of on average 100% recyclable packaging and 25% recycled content and of investing around 50 million euros in expanding its global recycling activities by 2025.

2019

PRT Wolfen is founded in Germany as a joint venture with the FROMM Group.

2019

Acquisition of the HDPE recycling companies Suminco and Replacal in Spain.

2020

ALPLA presents a carbon-optimised PET recycling process by switching the recycling process to green electricity and offsetting the residual unavoidable emissions with carbon certificates together with the ALPLA customers.

2021

Construction of ALPLArecycling Anagni, Italy.

2021

As part of a joint venture with Ecohelp and UPT, ALPLA invests in the building of a PET recycling plant in Târgu Mureș, Romania.

2021

Acquisition of BTB PET-Recycling based in Bad Salzuflen, Germany. The company turns used PET bottles into recycled material.

2021

Opening of a new HDPE recycling plant in Toluca, Mexico. At the same time, it is announced that the recycling capacity will be doubled from the second half of 2022.

2021

Increase in the investment target for the area of recycling to 50 million euros a year as part of the New Plastics Economy Global Commitment.

2022

Groundbreaking ceremony for construction of the new PLANETA PET recycling plant in Cunduacán, Mexico. The project is made possible by a joint venture between ALPLA and Coca-Cola FEMSA.

2022

Acquisition of the recycling company Texplast from the FROMM Group and all of its shares in the joint venture PET Recycling Team Wolfen. Significant increase in the annual processing volume in Germany.

2022

Commissioning of the Envicco recycling plant for PET and HDPE in Rayong, Thailand, in collaboration with PPT Global Chemical.

2023

Start of production at the modern PET recycling plant in Târgu Mureș, Romania, as part of a joint venture with Ecohelp and UPT. The annual capacity is 18,000 tonnes of rPET.

2023

Up to 87% CO2: a new calculation of the product carbon footprint confirms the climate protection effect of recycled plastics.

2023

ALPLA pools all recycling activities under the new ALPLArecycling brand.

2024

New ‘Planeta’ recycling plant in Mexico: After the foundation stone was laid in 2022 and 2023, approval for all lines and the ramp-up of production will take place in 2024.

2024

The new recycling plant in Ballito, South Africa, is currently under construction. The first machines will be installed in the near future with a view to starting production in 2024.

2025

ALPLArecycling joined the Brazilian HDPE recycling company Clean Bottle at the beginning of 2025 and acquired a majority stake in the joint venture. The annual output capacity is 15,000 tonnes.

Q&A

How much used packaging is actually recycled?

This depends above all on the recyclability of the packaging and on the collection infrastructure that exists in each country. According to data collected by the European Union, around 46 per cent of all plastic packaging was recycled in Europe in 2020, compared with just 24 per cent in 2005. But the most important thing is that the recyclate is used to produce packaging again. According to the Ellen MacArthur Foundation, global recyclate usage increased by around 108 per cent between 2018 and 2021, from 4.8 per cent to 10 per cent. This may not seem much at first, but it’s worth remembering that this volume is kept in the very high-quality packaging loop. Thousands of tonnes of virgin material can then be saved every year. Used plastics are therefore an excellent material that must be sorted and recycled even more systematically. ALPLA supports this goal on a global basis with its own recycling plants and partnerships.

Why can’t all used packaging be recycled? How can this be improved/changed?

When developing new packaging, ALPLA applies the principles of design for recycling. From the very beginning of the life cycle, the ALPLA experts make sure that plastic packaging is optimally suited to recycling. Packaging made of composite materials or multilayer films often poses a problem. Recycling such packaging is a complex process. We already have answers to this problem too and have developed a bag-like refill pack made of HDPE which is 100 per cent recyclable.

Does ALPLA only use recyclable materials or does it also use plastics that cannot be recycled?

ALPLA’s goal is for all packaging to be 100 per cent recyclable by 2025. The types of plastic used – predominantly PET (56 per cent*) and HDPE (39 per cent*), and PP and LDPE in considerably smaller quantities – are generally very easy to recycle. There is still room for improvement in some areas: for example, if a bottle and cap are made of different materials or additives are added that could affect the quality of the recyclate. ALPLA’s packaging solutions will be further optimised in this regard in the years to come on the basis of systematic design for recycling.

[* Figures for 2022, percentage of total material consumption]

What does plastics recycling do for the environment? Is it even worth it?

Recycling closes the loop and prevents used packaging from ending up in the environment. The recyclates can then be used to produce new packaging. This conserves both fossil and renewable resources as a base material for plastics. Recycling additionally makes a significant contribution to climate protection. Recycled plastics cause up to 90 per cent fewer greenhouse gas emissions than virgin material.

Why is so much plastic waste incinerated?

Plastic waste should only be incinerated if neither mechanical nor chemical recycling is ecologically or economically viable. If this is the case, waste incineration is better than landfilling as the calorific energy of the plastics is, at least, used in the form of heat. Landfilling should be completely avoided. Recycling quotas are constantly on the rise as a result of the global development of recycling plants and increasing improvements in sorting and recycling technologies.

Are recycled plastics safe or are they harmful to our health?

Only approved materials may be used for packaging production. The regulations for the packaging of food and drinks in particular are very strict. ALPLA and external partners check the quality on a regular basis.

Why is packaging made of recycled plastics better for the environment?

Scientific studies show that packaging with a high proportion of recycled plastics has a lesser impact on the environment as producing recycled materials causes fewer greenhouse gas emissions than the production of virgin materials. This has a very positive impact on the environmental footprint of packaging with high proportions of recycled material.

Why can’t all packaging be made of 100 per cent recycled plastics?

There is already packaging out there that consists of 100 per cent recycled plastics, for example for mineral water and cleaning products. However, the recycling quotas are not yet high enough to cover all the material needs for the production of packaging. The proportion of recycled materials in packaging is going to rise further, due in part to laws along these lines. Nevertheless, a certain proportion of virgin material will also be necessary in future.

What does PCR stand for?

PCR is an abbreviation that stands for ‘post-consumer recycled’. Recycling at ALPLA is about the mechanical recovery of plastics after use. And we take the term ‘post-consumer’ to mean packaging which is disposed of by end consumers (households) and then collected and pre-sorted by waste disposal companies. The packaging is subsequently pressed into bales according to the recycling companies’ specifications, transported to the recycling companies and turned into rPET and rHDPE pellets – always with the properties set out in our data sheets. PCR is therefore different to PIR (post-industrial recycled).

What’s the difference between mechanical and chemical recycling?

With mechanical recycling, the material is physically converted. The polymer remains unchanged in terms of its structure throughout the recycling process.

With chemical recycling, the material is converted at the chemical level. Polymers, for example, are broken back down into their monomer components and are recomposed.

For us at ALPLA, recycling first and foremost means mechanical bottle-to-bottle recycling.

What is the ‘waste hierarchy’?

The waste hierarchy ranks waste treatment in order of priority. At the top is waste prevention, followed by waste reuse or preparation, for example by cleaning or repairing it. The next level is recycling, followed by recovery such as incineration. And at the bottom is the use of waste for landfilling – something which should ideally be avoided.

What’s the difference between ‘design for recycling’ and ‘design from recycling’?

Design is a broad term used in a variety of areas including art, architecture and fashion. At ALPLA too, packaging design serves all kinds of important purposes such as information, protection and practicability as well as sustainable aspects like recyclability, reusability and lightness. Our aim is to design packaging in such a way that it can be recycled in accordance with the bottle-to-bottle principle on the one hand and can consist of the most sensible proportion of recycled materials both economically and environmentally speaking on the other. This is what’s known as ‘design from recycling’. Overall, therefore, we follow the concept of ‘design for circularity’.